IF ever a company could be justified in having a spring in its step it's Skipton's John Binns and Son.

For the firm is celebrating 120 years of manufacturing springs and wireform, most recently at its premises at the Airedale Business Centre, Keighley Road.

When it started in 1895, the company originally specialised in the supply of compression, tension and torsion springs to the textile industry.

During the Second World War, it supplied springs for tanks - and recently, as a one off job, it was involved in a project to supply springs for the restoration of an M24 Chaffee tank.

In 1967, under the guidance of the late Alan Driver, the firm pooled its resources with the Bradford Spring Co to form John Binns & Son (Springs) Ltd.

In 1993, the late Trevor Driver moved the company to a brand new, purpose-built facility in Skipton which has been its home ever since.

And since then, Nicola, Christian and Alex have become the third generation of the Driver family to be appointed directors. They have continued the policy of investing in the latest equipment to keep them at the forefront of an industry which plays an often unrecognised but absolutely vital part among the building blocks of 21st century engineering.

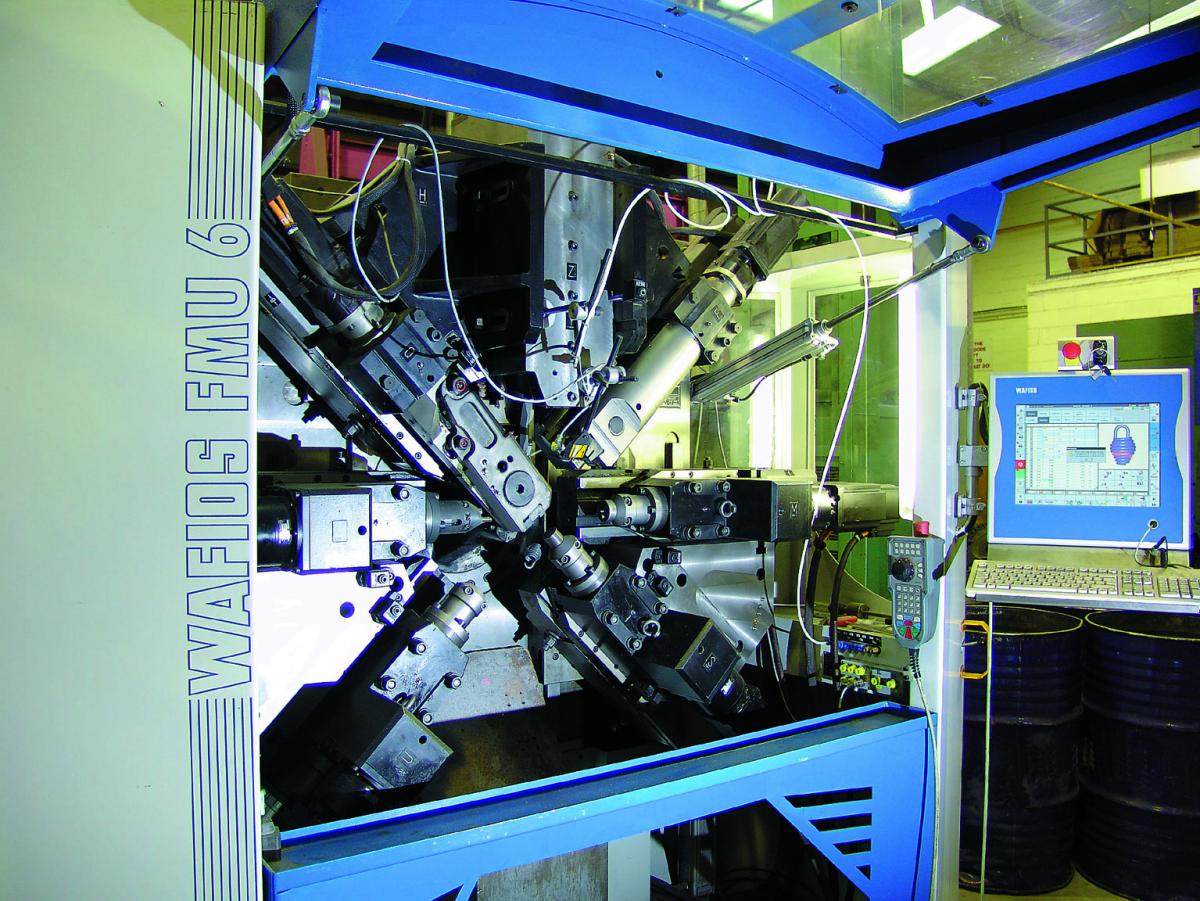

In 1999, the first "computerised numerical control" machinery was purchased - the start of a huge change in the manufacturing landscape.

Five years later, a powder coating facility was introduced, and in 2013 a 3D production system was installed to help their customers make design decisions and improve the company's quality of service.

This year, two brand new pieces of spring-making machinery have been purchased to increase production in the larger wire sizes.

This investment in machinery has also been mirrored in the human element - the company's workforce.

In keeping with the current drive in British manufacturing, in the last 18 months John Binns has taken on three apprentices.

The company now employs 20 people, and investment in new camera and laser equipment has made for "maximum accuracy and efficiency", says the firm's sales director David Whitfield.

“Even at the depths of the recent recession, we looked to invest in the latest spring making machinery as well as our staff.

“We now have a modern manufacturing facility, which allows us to compete successfully with other spring suppliers both in the UK and worldwide.”

The new machinery has given the company the capacity to manufacture in production runs of millions or in much smaller quantities. John Binns and Son looks set to take on the next 120 years with confidence.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here