THIS year will see the publication of a special edition of a book which explores what it meant to live and work in Yorkshire more than 50 years ago.

"Life and Tradition in the Yorkshire Dales" written by Marie Hartley and Joan Ingilby and championed as a masterpiece when first published, is being re-issued by the Yorkshire Archaeological & Historical Society.

To mark the anniversary a series of events will run throughout the year inviting people to have a go at wall-building, scything, haymaking, dairying, or sheep washing, knitting and making items such as rugs, shoes or besom brushes, not to mention a chance to taste traditional farmhouse food.

And its that challenge to try traditional tyke scoff that has intrigued award winning cheesemonger, Andy Swinscoe at his Courtyard Dairy near Settle.

He has a bee in his bonnet about promoting traditional Yorkshire Wensleydale cheese and wants to get more people to experience to its special flavour and texture.

So he has set himself the challenge of replicating Wensleydale cheese exactly as it was done in the 1930s and to reveal it at the Yorkshire Dales Cheese Festival in September.

But he needs help. "I'm appealing to people who have cheese making skills or might have a traditional recipe hidden away to help me out," said Andy.

"Modern science has changed things massively over the last 50 years and mass produced farmhouse cheese is made very differently today.

"It was traditionally made by the farmer's wife and it took a long time. She would make it in those periods of brief inactivity when she had time from her other chores. It could take up to 12 hours but it was not a constant thing.

"To make sure we do this as accurately as possible, we're asking anyone who knows about historical Dales cheese-making to get in touch.

“We’d like to find out as much as there is to know about how small farms and housewives made cheese on the farm and in their own homes.

"The book is useful as a record of the way people historically lived and farmed in the Dales, but we’re seeking to find out even more about cheese-making in particular.”

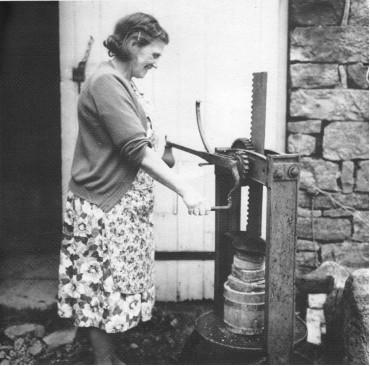

“We suspect that many people have cheese-making items, photographs or information hidden away in lofts and cupboards – treasures that would be seriously useful to us to help discover exactly how farmhouse cheese was made in those days.

“Over the last year we’ve luckily discovered some farmers’ wives’ hand-written cheese recipes, and a few bits of equipment, but we know there’s much more out there – we think that many people could have hidden gems in their attic or stored away, and we’d love to see them”

Andy is asking that anyone who has any information, notes or equipment that are related to Dales cheese-making, or that might have been used to make cheese or butter in the Dales, to contact him on 01729 823 391 or by email to andy@thecourtyarddairy.co.uk.

“Please get in touch if you have anything of interest and help me to build up the most detailed profile ever of Wensleydale, the most traditional of Yorkshire cheeses," he said.

Andy has supplied a recipe for a cheese known as 'smallholder', a fairly basic hard-cheese that many small farms and house-wives would make with surplus milk as cheese for home consumption.

Ingredients: 8L milk, 20g salt

A 40cm square of muslin

8ml rennet, 1 packet cheese bacteria such as MA400 (for 8l); both available from health food shops or online retailers like www.cheesemaking.co.uk.

Method

Heat the milk to 32C, then turn off the heat.

Add cheese bacteria stir well in, then leave for 1 hour, with the lid on.

Stir in the rennet, then leave un-agitated for 45 mins. Using a whisk, cut the curd up into 1cm bits. Leave for 5 mins to settle , then stir with a spoon gently for 30 minutes, slowing raising temp to 37C.. Remove from heat and drain off the yellow whey from top.

Pile the curds into a square of muslin, the gather up cloth into bundle with one corner looped around three,

Leave the curd in this bundle for 60 minutes, but tightening the loop (squeezing the curd every 15 minutes). After this hour, curd should be matted but flaky.

Break up the blocks of curd into hazelnut sized pieces. Add in the salt and mix through well.

Pack this salted curd into a collander lined with cloth, and press by hand as firm as possible. to remove the moisture

Turn and press again every hour or so till you go to bed!

(For better results, rather than pressing by hand put the curd into a cheese-mould or something similar and press using weights on top overnight)

Remove from collander/mould, and ripen in cool cellar/garage (10-12C), within a plastic tub.

Turn frequently at first, less often as ages. Rub back/tap down mould once forms coat.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here