AS pilot Richard Mavor parked the Boeing 777 at Heathrow on Feb 7, 2020 and disembarked 250 passengers having arrived from Abu Dhabi, he was blissfully unaware that this would be the last time he would be at the controls of this mighty airliner until June.

As an instructor and examiner on the aircraft, the Embsay resident was preparing himself for a seven-day stint in the flight simulator overseeing the airline’s pilots undergo their six-monthly assessments.

As March progressed, along with Covid-19, all non-essential training was cancelled and, like many businesses, staff were all sent home.

“The future was incredibly uncertain and so I began to dig in for a long wait,” Richard explained.

“The financial hit was considerable so I had to consider ways and means of tightening our belts as we waited it out.

“I have always been very much the outdoor type and keep myself very physically fit. Long-distance hiking and camping were always my regular activities.

“As such, I began to plan for when times became better. Home schooling of our two young children would also take up much of my time.

“Aside from regularly purchasing (frequently too much!) equipment, I also enjoy manufacturing small items for my adventures. I have taught myself how to work with leather and produced such items as knife sheaths and various leather cases.

“I have always used YouTube as my means of learning a skill and contribute back to the viewing community with my own YouTube channel – I now have about 3,500 subscribers. My first YouTube offerings concentrated mainly on making decent food for camping expeditions using dehydration as my main skill. I was keen to show that you can use the freshest of ingredients and no preservatives are needed just so long as you thoroughly dehydrate the meal prior to storing.

“I wanted to expand the subject matter of my videos so began to include small extracts from my leatherwork. Again, these were found to be popular so I began to diversify the content of my videos where I would further showcase my little demonstrations – two types of stoves made from drinks cans, for example.

“On the subject of stoves, I have always had a fascination about different ways of producing heat for cooking. One of my favourite stoves is simply a steel cube with an open top which is fuelled with small logs and twigs.

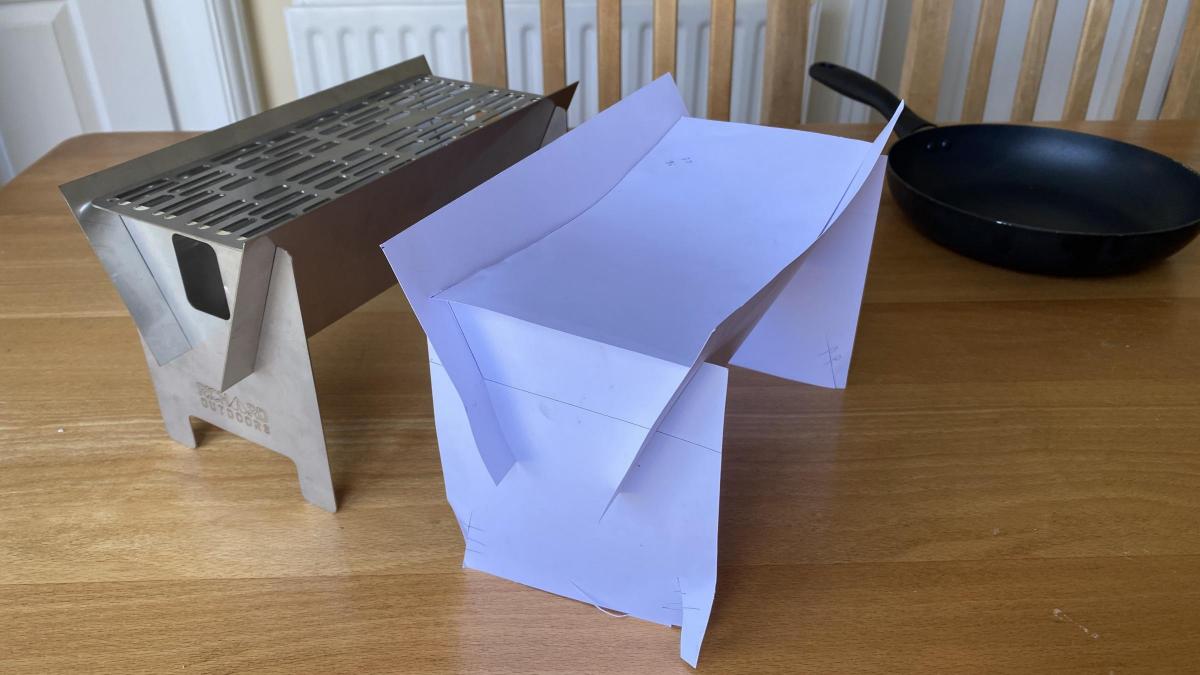

“From another project, I had some thin stainless-steel sheet left and had planned one day to make my own twig-burning stove. My initial plan was simply to follow the traditional cube shape and I was just about to start etching the outline in the steel when I had another thought. A cube shaped stove can only do one thing at a time, either boil a pot of water or heat food on a grill. I thought, why not just extend the cooking surface area so both can happen at the same time? It didn’t need to be much bigger and would pack flat so as to remain portable and therefore still of use to the backpacker.

“As this was to be a new design, I thought it would be best to first make a cardboard model of the picture that I had in mind.

“Earlier in the year, I had become friends with a like-minded individual in the village after he had got me out of a pickle with my stubborn laptop. I thought he’d be just the person to take a look at my proposition and see if the idea had legs. It seemed that after just a few keystrokes, Steve had transferred my flimsy cardboard model into a 3D image on his computer. Slowly and surely after many, many cups of tea and head-scratching, we began to think that this idea might evolve into something usable. The idea grew in our minds and on-screen and we eventually came up with an end product that looked good, was unique and, above all, would work.”

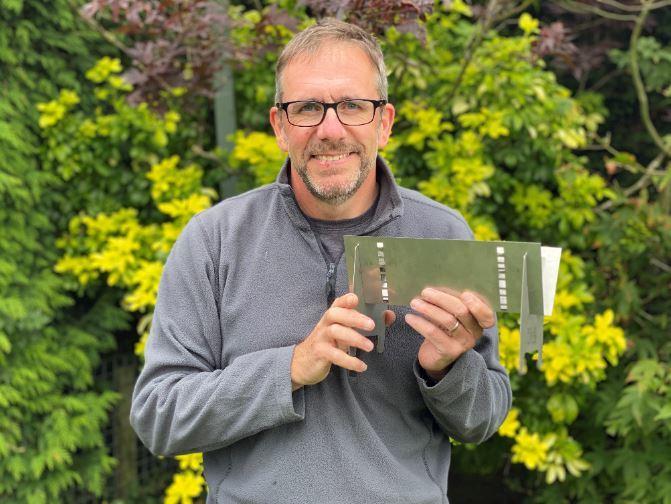

Richard contacted various sheet-metal factories and sent the plans over. In a matter of days an example stove was sent over providing a tangible return for all the effort. Richard said it was ‘unbelievably exciting’.

He said: “I showcased the stove on my YouTube channel and it received a great deal of positive feedback as well as some useful developmental ideas. In the meantime Steve and I had thought about some improvements which we adopted and eventually produced the modified stove; we named it The Fire Trough ™ and decided it was a marketable item.

“Another YouTube showcase video announced the sale and orders came through as soon as the new video was live. Through word-of-mouth and further advertising on Instagram, sales have continued to come thick and fast.

“In essence, the Fire Trough™ is unique. The very shape of the stove lends itself to convenience. It assembles and disassembles in seconds and can be used with small twigs or charcoal; at 900g, it is highly portable,” Richard added.

Also included is an adapter which allows two spirit or gas burners to be fitted, should the user need to get cooking when time is of the essence.

The end product is a device made in the UK using British engineering and materials. The services of two talented ladies in the village were secured who sewed some high-quality pouches for the product and ensure that the stove is packed in a good quality box with a note and instructions personally signed by myself.

“This has been an exciting venture and has certainly filled in my spare time generated by Covid-19. Although many aspects have been way out of my comfort zone (I’m not a businessman) it has been extremely exciting to make an invention that actually works and people want to buy.”

The stove, priced at £59.99, has been trademarked as the Richard Outdoors and Fire Trough™ brand names and already an enormous amount of feedback has been received from satisfied customers from as far afield as Europe, the USA, Canada and Australia.

So what next? Richard said that aside from keeping up with current orders, he is looking to market his product to the wider community and will be contacting high profile specialists/magazines in the bushcraft and camping arena to review the stove.

A titanium version is currently being priced which would be about 1/10th of the weight but also much more expensive to produce so a lot of thought is being afforded to this avenue in respect of profit margins and still maintaining a top-quality product.

A couple of ideas for equipment to further simplify and lighten the load of the outdoor-minded community are also been investigated.

Richard said that he is extremely pleased and somewhat surprised to have produced such a handy little addition to the kit for an enthusiast.

“The stove will cover every eventuality whether you are a backpacker, caravanner, bike-packer, tourer….the list is endless.”

For more details look at YouTube: Richard Outdoors, the Facebook page: https://www.facebook.com/Richard-Outdoors-110734940745527or Instagram: Richard_Outdoors66.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here